No-Code Robotic Programming

Laser Clean’s user-friendly interface allows MRO technicians to program robotic cleaning operations in just a few clicks, eliminating the need for robotics specialists.

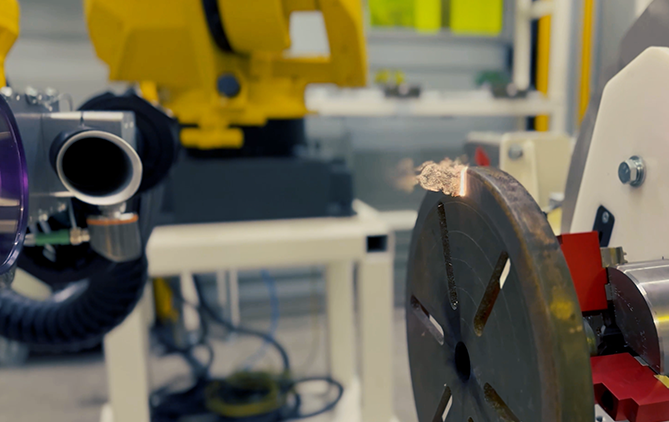

Ditch Hazardous Chemicals for a Clean, Sustainable Solution

Traditional cleaning methods expose operators to harmful chemicals and generate toxic waste. With Laser Clean, you eliminate chemical treatments, reduce environmental impact, and create a safer work environment—all while maintaining top-tier cleaning performance.

5x Faster Cleaning for Maximum Efficiency

Manually cleaning turbine parts is slow, inconsistent, and labor-intensive. Laser Clean automates the process, cutting cleaning time by up to 80%, reducing manual effort, and lowering operational costs.

Advanced Automation—No Robotics Expertise Needed

Unlike traditional robotic solutions that require specialized programming, Laser Clean’s intuitive interface allows technicians to simply select surfaces to clean. The system generates optimal robotic trajectories automatically, ensuring fast deployment and consistent results.

Laser Clean removes oxidation and coatings with micron-level accuracy, preserving critical components and extending their lifespan.

Laser Clean’s user-friendly interface allows MRO technicians to program robotic cleaning operations in just a few clicks, eliminating the need for robotics specialists.

The system generates optimal laser paths to ensure high-precision cleaning while protecting delicate turbine components.

Laser Clean processes turbine parts 5x faster than traditional methods, reducing downtime and improving maintenance throughput.

Compatible with existing MRO workflows, Laser Clean supports 3D recognition for various part geometries without requiring custom tooling.

Expertise in residual stress and laser technologies

Our engineers and technicians offer you complete product and service solutions in the field of residual stress measurement, non-destructive testing (Barkhausen Noise) and laser surface preparation.

Website: https://meliad-sas.com/fr/entreprise

Request a demo today and see how Laser Clean can transform your MRO operations—safer, faster, and more cost-effective than ever.