Choosing The Right Robot Programming & Simulation Software

- 11 mins read

What is the best robotic programming and simulation software for me?~Pretty much everyone getting into industrial robotics.

Well, the answer is… It kind of depends. There are a lot of tools out there. For a newcomer this can be truly overwhelming. So in this article we are going to do our best to give you some bearings to help you choose the right tool for your needs.

How do you choose the best programming and simulation software for your industrial robot? This is a question that is difficult to answer instantly, whether you are an expert or beginner in robotics.

There are several factors to consider when selecting a programming and simulation environment. Here are a few things to consider to help you go through your decision process:

- Accessibility: not everyone is an expert in programming, maybe you don’t even have any expertise in robotics at all. Choosing a simple environment that is accessible and easy to use to the greatest number of people without sacrificing performance can be a profitable choice to accelerate your growth.

- Brand compatibility: not all programming and simulation environments guarantee compatibility with all robot brands. So keep an eye on which robot works with which software.

- Multiplicity of applications: a software may be perfect for a one type of application, but wrong for others. The versatility of robots in the industry is increasing, so anticipate your current and future needs.

- Ability to handle real-time data: In the industry, robots often have to react quickly to real-time data, so it is important to choose a programming and simulation environment that can handle this effectively.

- Security: Industrial robotics systems can be exposed to safety risks and hazards, so it is important to choose an environment that guarantees the protection of operators and physical hardware, offering robust security features.

The right robot platform that fit your needs

To make a decision, you always have to keep in mind your intended application, the environment in which your robot operates, the required level of autonomy, the desired level of customization, and budget constraints.

Ultimately, the best platform for your needs will depend on the specific requirements of your project. To make your evaluation process easier, we’ve put together a list of the best solutions you may find on the market :

- Fuzzy Studio: intuitive no-code robotic programming and simulation – no robotics or coding skills required.

- Delmia: simulate from the robot to the complete virtual factory

- KineoWorks: a powerful path planner and collision detector

- MoveIt Studio: maintenance oriented with debug and diagnose features

- Ready Robotics: a user-friendly operating system

- RoboDK: a complete OLP solution with extensive brand compatibility

- Vention: handle the complete lifecycle of the robot

- Visual Components: full simulation of a production line

- Wandelbots: a fast and out-of-the-box programming interface

Fuzzy Studio

Pricing: Starting 96€/month

Today’s solutions for creating robotic cells are often complex; with Fuzzy Logic, this process becomes incredibly simple and accessible. Fuzzy Logic provides an intuitive environment for designing, integrating and operating robotic work cells. Unique in the market, it allows users who are not experts in robotics or programming to create their own robotic cell. The software focuses on the essentials: a large library of robots, tools and objects. CAD systems can also be imported with a single click. This interactive virtual cell is designed to be intuitive and easy to use. In simulation, basic specifications can be validated immediately, at low cost and with software that requires no robotics expertise. It is also interactive, displaying key information about the design to facilitate decision making before moving into the real world. They can be quickly modified in simulation.

Fuzzy Logic includes collision detection to instantly validate cell sizing. Object positions are configured and visible in minutes, and potential sources of collision between objects in the scene are anticipated. Static links between objects are possible using a scene tree. As the position of an object changes, the trajectories associated with that object are updated as necessary. Interactions are dynamic, so the feasibility of the robot’s trajectories is immediately apparent.

Robot trajectories require complex and time-consuming programming by a roboticist. With Fuzzy Logic, the same complex trajectories are generated in a few clicks, both on the contours and on the surface of a part, saving considerable time. An unlimited number of points can be added to these trajectories, within the technical limits of the robot. By making trajectory generation available to everyone, manufacturers are no longer dependent on robotics experts.

With Fuzzy Logic, you can also add a link to the robot for real-time control. This control validates all assumptions made in the simulated cell, trajectories, execution and collisions in the real world. With fast simulation, the risk of error is reduced to almost zero. If a problem is detected, it can be easily corrected directly in the simulation. An I/O module allows you to simulate the behaviour of a PLC in the virtual cell, easily simulated and programmed with simple functions such as generating a path or triggering a gripper, without requiring any special programming knowledge.

![]()

Fuzzy Logic also offers an innovative real-time operating system, designed to be a universal interface between robot controllers and the user environment, primarily for use on embedded systems with a real-time operating system for robot control or on any system for test purposes. It allows you to quickly and easily develop your own applications without any robotics expertise, responding to the strong demand for an open interface accessible to a wide range of users. It ensures full interoperability with ABB, Fanuc, Kuka, Staübli, Universal Robot and Yaskawa environments.

Delmia

Pricing: on-demand

Delmia is a brand of software solutions provided by Dassault Systèmes. One key feature of Delmia’s digital manufacturing solutions is its ability to simulate and optimize manufacturing processes in a virtual environment before they are implemented in the real world. This allows companies to identify potential issues and make changes before they become costly problems. The software also allows for the creation of digital twins, which are virtual representations of physical assets, such as machines and tools, that can be used for training, testing and simulating the performance of the equipment. The software allows for the programming, simulation and testing of robots, helping companies to optimize the use of robotics in their operations.

Delmia also provides solutions for the management of industrial operations, including scheduling, production planning, and supply chain management. These solutions enable companies to coordinate and optimize their operations.

KineoWorks

Pricing: on-demand

KineoWorks is a software solution that provides a set of tools for automating the creation and optimization of motion trajectories for robotic systems. It is designed to make it easy for engineers and researchers to create, test, and refine motion trajectories for a range of robotic systems, including industrial robots, service robots, and humanoids.

The software features a user-friendly interface that allows users to create and edit motion trajectories using a variety of tools, including a graphical editor, a motion planning module, and a motion optimization module.

In addition to its trajectory creation and optimization capabilities, KineoWorks also provides a number of features that allow users to easily integrate their robotic systems with other systems, such as sensors and actuators. The software supports a range of programming languages, including C++, Python, and MATLAB, making it easy to integrate with other software tools and frameworks.

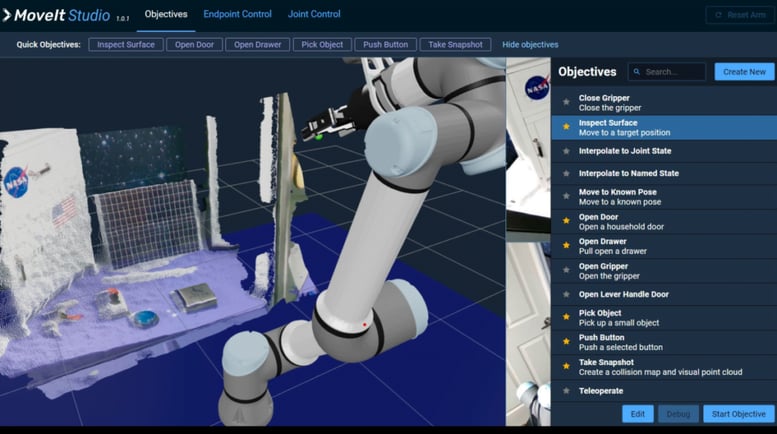

MoveIt Studio

Pricing: on-demand

MoveIt Studio is a solution for robot motion planning and control. The software is based on the open-source MoveIt framework. With MoveIt Studio, users can create and test motion plans using a variety of planning algorithms and controllers. The software also allows users to visualize the robot’s motion in real-time, providing a simple way to debug and optimize motion plans. Additionally, MoveIt Studio can be integrated with other software, such as ROS (Robot Operating System), to provide a complete solution for robot control and automation.

MoveIt Studio also provides tools for collision checking and avoidance. This allows users to ensure that the robot’s motion plans do not collide with any obstacles or other objects in the environment. The software also includes a library of pre-configured robot models, making it easier for users to get started with the software. Furthermore, MoveIt Studio allows users to import and export motion plans in a variety of formats, to share plans with others or integrate them into other software.

Ready Robotics

Pricing: on-demand

Forge OS and Forge SDK are software development tools provided by Ready Robotics. Forge OS is an operating system that runs on the robotic arms and provides the necessary infrastructure for running applications on the robot. It includes a real-time kernel, device drivers, and other system services. Forge SDK is a software development kit that allows developers to create applications that run on the robot. It includes libraries, sample code, and documentation that make it easy for developers to create applications that control the robot’s movement, as well as integrate with other systems such as sensors and cameras.

Together, Forge OS and Forge SDK provide a platform for developing custom robotic applications, which can be used in a range of industrial settings. Ready Robotics also provides a feature that allows for the integration of the robotic systems with other systems such as PLCs, sensors and cameras. This enables the robots to interact with other equipment in the production line, as well as to collect data from various sources. The collected data can then be analyzed to optimize the performance of the robot and to make better decisions. This integration feature also allows for remote monitoring and control of the robot, which can be done through the cloud-based system. This allows for the robot to be controlled and monitored from any location, which can be very useful in situations where the robot is deployed in a remote location.

RoboDK

Pricing: 3995€ for a permanent license

RoboDK is a software solution for robots and CNC machines. It allows users to simulate, program and optimize robots and CNC machines in a virtual environment. This enables users to reduce the time and costs associated with prototyping and testing, as well as improve the quality and accuracy of their products. RoboDK supports a wide range of robots and CNC machines from various manufacturers, including ABB, Fanuc, KUKA, Motoman, and Universal Robots. With RoboDK, users can program robots using a drag-and-drop interface, or using scripting languages such as Python or C#.

The software also allows users to import 3D models of parts and tools, and to simulate the entire production process in a virtual environment. Furthermore, RoboDK includes a library of pre-built robot programs and post-processors, which makes it easy for users to program robots for specific tasks. Additionally, RoboDK provides a cloud-based collaboration platform that allows users to share and collaborate on their robot programs and simulations with others.

Vention

Pricing: 6000€/2 years/per machine (MachineLogic with Robot)

Vention is a platform that allows users to design, order, and assemble custom industrial equipment. The solution provided includes an interface that allows users to create custom designs using pre-built modular parts. These designs can then be ordered and assembled on-site, reducing lead times and simplifying the equipment manufacturing process. Additionally, the platform offers features such as simulations and collision detection, which help users create functional designs. Vention also provides resources and support options to help users. This includes a library of pre-built parts, tutorials and guides on how to use the platform, and a community forum where users can share their designs and ask for help from other users.

Additionally, the platform offers a variety of integrations with other tools such as CAD software and inventory management systems, making it easy to integrate into existing workflows. Furthermore, the platform also allows for real-time collaboration, where multiple users can work on a single design simultaneously.

Visual Components

Pricing: on-demand

Visual Components is a company that provides 3D manufacturing software and solutions for various industries, such as manufacturing, education, and research. Their software allows users to create realistic 3D models of equipment, machinery, and factories, as well as simulate their behavior and performance. This can be used for a variety of purposes, such as design, planning, training, and virtual reality applications. Additionally, Visual Components offers a range of hardware and software products, such as 3D scanners, cameras, and VR headsets, to support the creation and use of 3D models. Visual Components provides services to support their clients such as training, consulting, technical support, and custom development.

They also have an online marketplace where users can purchase and download pre-made 3D models and components. They also have a Community Hub, a platform where users can share their knowledge, collaborate and connect with other professionals in the field. They also offer a range of software tools to support the use of 3D models in manufacturing, such as tools for measuring and analyzing performance, and tools for creating animations and presentations.

Wandelbots

Pricing: starting 499€/month

Wandelbots specializes in developing software and hardware solutions for industrial robots. Their main product is a software platform that allows users to program and control industrial robots without the need for specialized programming knowledge. The platform is based on an interface that allows users to create and edit robot programs using drag-and-drop functionality. The platform also includes a library of pre-built functions and modules that can be used to create complex robot programs. One of the key features of Wandelbots software is its ability to learn from human demonstration. This allows users to show the robot how to perform a task, rather than having to manually program it. The software can then automatically generate the necessary code to execute the task.

Wandelbots develops also a mobile app that would allow users to control their robots remotely and monitor their performance in real-time. This would enable companies to monitor and control their production lines from anywhere.

And that’s just the tip of the iceberg!

As mentionned earlier, the list above is far from being exhaustive. Several other solutions also exist on the market that may catch your interest. We can name a few of them: Augmentus, Realtime Robotics, Octopuz, Robotmaster, Energid…

If you already feel comfortable with robotics, and use a specific brand, you may have been in touch with one of the following environment : RobotStudio (provided by ABB), Roboguide (provided by Fanuc), MotoSim (provided by Yaskawa), Kuka.sim (provided by Kuka) or even Staübli Robotics Suite (provided by Staübli). These solutions are mainly used by engineers and dedicated technicians, and are considered expert robotics programming softwares, providing a wide range of advanced features. They are commonly used in industries such as automotive, electronics or food and beverage.

On the same topic, you may also find application-oriented programming environments. As you may guess, these softwares are not focused on versatily but will give you full control on all the parameters and settings you can ever dream of if you work in a very specific area of production, like welding, machining, 3D printing… In this family of sofwares are solutions like Adaxis or AI Build (additive manufacturing), Path Robotics (welding), GrayMatterRobotics (sanding), SprutCam (machining)…

What’s next?

We understand the importance of staying informed and up to date in today’s fast-paced industry, which is why we invite you to join our community. By subscribing to our newsletter, you’ll have access to our latest news, exclusive blog content and offers.

We also invite you to follow us on our social media platforms, where you’ll be able to connect with other experts and professionals in your field. We want to share valuable insights, tips and resources, and we encourage you to join the conversation.

But we know that sometimes it’s not enough to just read or hear about a solution, you want to see it in action. That’s why we invite you to schedule a call with one of our experts who will be happy to show you how our solution can help you achieve your goals, answer any questions you may have, and provide you with more information.

Don’t wait, take action now and join our community of informed and successful professionals. Together we can achieve Automation Independence.

-1.jpg?width=2000&height=1335&name=WeldMate%20-%20Formulaire%20(1)-1.jpg)