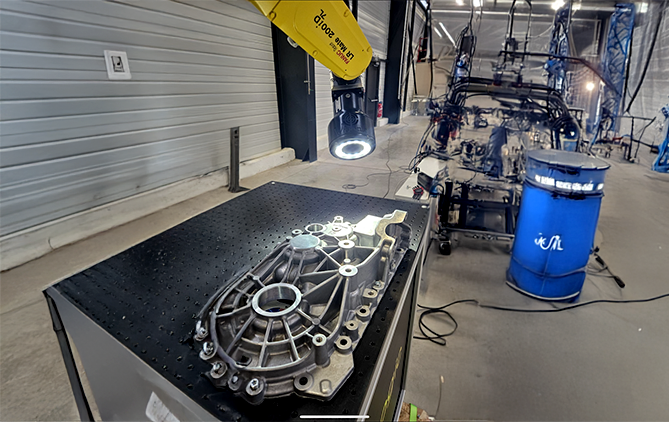

High-Definition Optical Inspection

Equipped with a digital matrix camera (chromatic, monochromatic, or NIR) for precise, high-resolution imaging.

Traditional vision systems struggle to keep up with fast-moving production lines, leading to missed defects and costly rework. RoboCheck™ ensures real-time, high-precision inspections at any speed—without slowing down operations.

Unlike static inspection setups, RoboCheck™ dynamically adjusts focus and exposure in milliseconds, regardless of robotic motion, acceleration, or orientation. No recalibration needed—just plug, play, and automate with confidence.

Most vision systems require extensive setup, costly recalibrations, and specialized expertise. RoboCheck™ offers seamless plug-and-play interoperability with Intellicheck©, minimizing setup time and ensuring long-term reliability with minimal maintenance.

Liquid lens technology adjusts depth of field in milliseconds, eliminating the need for manual focus changes.

Equipped with a digital matrix camera (chromatic, monochromatic, or NIR) for precise, high-resolution imaging.

Multi-spectrum annular LED sources provide optimal visibility across different materials and lighting conditions.

Liquid lens technology automatically adjusts for variable depth of field, eliminating repositioning needs.

Compact (148mm x 116mm x 116mm), robust, and easily integrated with standard M12 connections.

Visionic has 25 years experience in the Machine Vision field. Our team of experts are skilled in optics, IT, robotics, and in mechanical and electronic engineering. We can handle your project end-to-end from initial audit to manufacturing process upgrade the introduction of final product controls. Among our services are consultancy, engineering, feasibility and dimensional studies, design, solution modeling, prototyping, demonstrators, performance-based contracts, diagnostics, integration, deployment, end-user interface upgrades, machine code development, device installation, parameter setting, maintenance, assistance and training.

Website: https://www.visionic.fr/en/

Eliminate inspection errors, streamline automation, and boost production efficiency with RoboCheck™. Request a demo and see it in action!